Flowing grain can trap someone standing on it in just four to five seconds and that person will be completely covered in grain in about 22 seconds, according to the Grain Handling Safety Coalition.

Using appropriate safety practices when working around grain is vital. Make sure everyone working around stored grain understands the hazards and proper safety procedures.

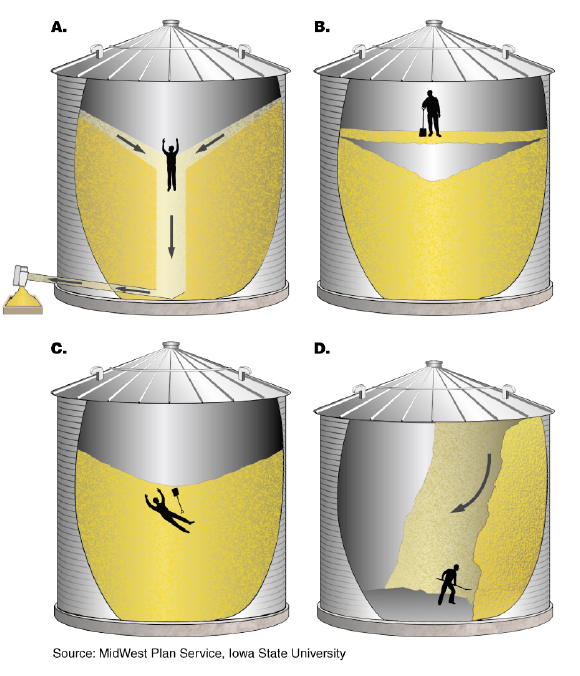

The most dangerous scenarios around stored grain involve flowing grain, bridged grain and vertical grain walls.

Flowing grain accounts for the majority of grain engulfment incidents and has become more dangerous as newer equipment unloads grain at faster rates. When grain is unloaded from below, such as in grain bins, grain piles, trucks and even grain wagons, anyone standing on the grain can be pulled down toward the outlet and are often stuck faster than they can react.

Bridged grain occurs when a crust or clumps of spoiled grain forms on top of the grain and grain is removed, leaving avoid space below the crust. The crust can collapse under a person’s weight, potentially burying them in the shifting grain. Stay outside the bin and use a pole or other object to break the bridge loose.

Vertical grain walls form when spoiled grain clumps stick to the wall and become dangerous when grain is dislodged and falls like an avalanche.

Follow these safety practices:

- Aim for zero entry into the bin. Never enter a bin while unloading grain or to break up a grain bridge. Flowing grain will pull you into the grain mass, burying you within seconds.

- Post warning signs on bins and at all entry points make everyone aware of the hazards.

- Restrict access to bins and piles so unauthorized people and youth can’t enter.

- Work from outside the bin and above the highest point of grain.

If entry is essential, use proper safe entry procedures including:

- Lock out and tag out all grain unloading equipment.

- Stop the grain-conveying equipment and use the “lock-out/tag-out” procedures to secure it before entering the bin. Use a key-type padlock to lock the conveyor switch in the “off” position to assure the equipment does not start automatically or someone does not start it accidentally.

- Have an observer nearby.

- Use a life harness

GRAIN BIN DANGERS

A. Never enter a storage bin while unloading grain, because flowing grain can pull you in and bury you within seconds.

A. Never enter a storage bin while unloading grain, because flowing grain can pull you in and bury you within seconds.

B. Grain kernels may stick together, forming a crust or bridge that isn’t strong enough to support a person’s weight after the grain below it is removed.

C. Don’t try to break a grain bridge or blockage loose from inside the bin.

D. Try to break up a vertical wall of grain from the top of the bin, not the bottom, because the grain can collapse and bury you.